PCC Blue: A Dive into Flexibility and Efficiency

- Elvira Rakova

- Dec 17, 2023

- 2 min read

In the dynamic landscape of industrial technology, the flexibility of pneumatic drives takes center stage. Traditionally viewed as a rigid technology, pneumatic drives, especially linear actuators, are undergoing a transformative shift to meet the demands of new machines and evolving production requirements. This article delves into the importance of this flexibility not only in terms of energy efficiency but also in performance optimization.

Pneumatic cylinders, the workhorses of these systems, are typically chosen based on a fixed pressure level and cylinder size, leading to inefficiencies and unnecessary energy consumption. A critical issue highlighted is the prevalent oversizing of pneumatic drives, with 90% of systems currently operating beyond their necessary capacity. The impact is significant: increased energy consumption, excessive use of compressed air, and a suboptimal performance ratio.

Consider a scenario where a machine needs to accommodate varying tasks with different force requirements. Traditional approaches lead to the selection of the largest cylinder, resulting in energy waste for the majority of tasks. This article explores a smarter alternative – a technology that adapts to changing force needs.

The focus shifts to a groundbreaking solution, the PCC Blue Cylinder, developed by Mader GmbH from Germany. This standard-sized cylinder incorporates a smart valve with integrated algorithms that dynamically adjust the input energy based on force requirements. The result is a system that can efficiently handle various forces, all with a single, adaptable cylinder.

The key lies in understanding the pressure and velocity profiles of pneumatic drives. By optimizing the pressure difference and flow rates, the PCC Blue Cylinder achieves substantial energy savings without compromising performance.

Practical examples and economic calculations emphasize the significant cost savings achievable through this innovative technology.

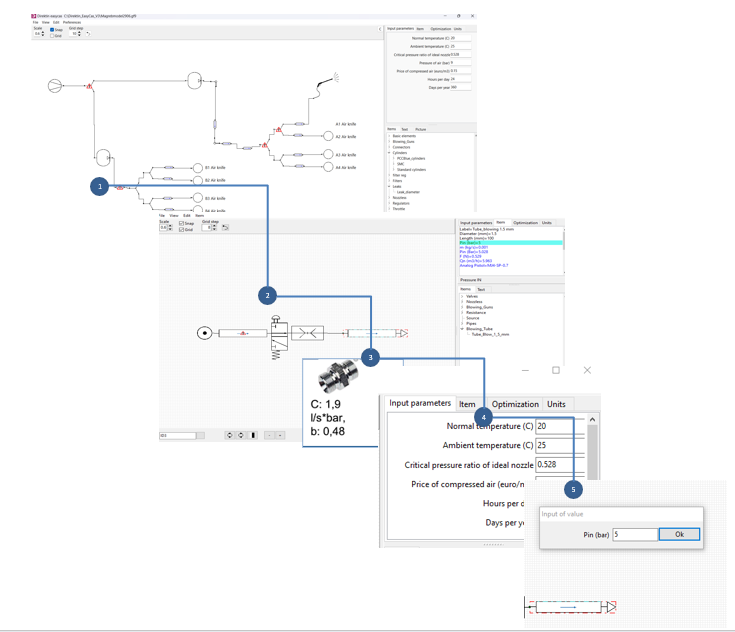

To facilitate further exploration and calculation of potential savings, the article encourages readers to utilize Direktin software with an integrated PCC Blue Cylinder model. By downloading the software, users can assess the economic benefits of adopting this flexible pneumatic drive technology for their specific applications.

If you are keen to learn more about the technology, contact Marina Geisinger.

.

Comentarios